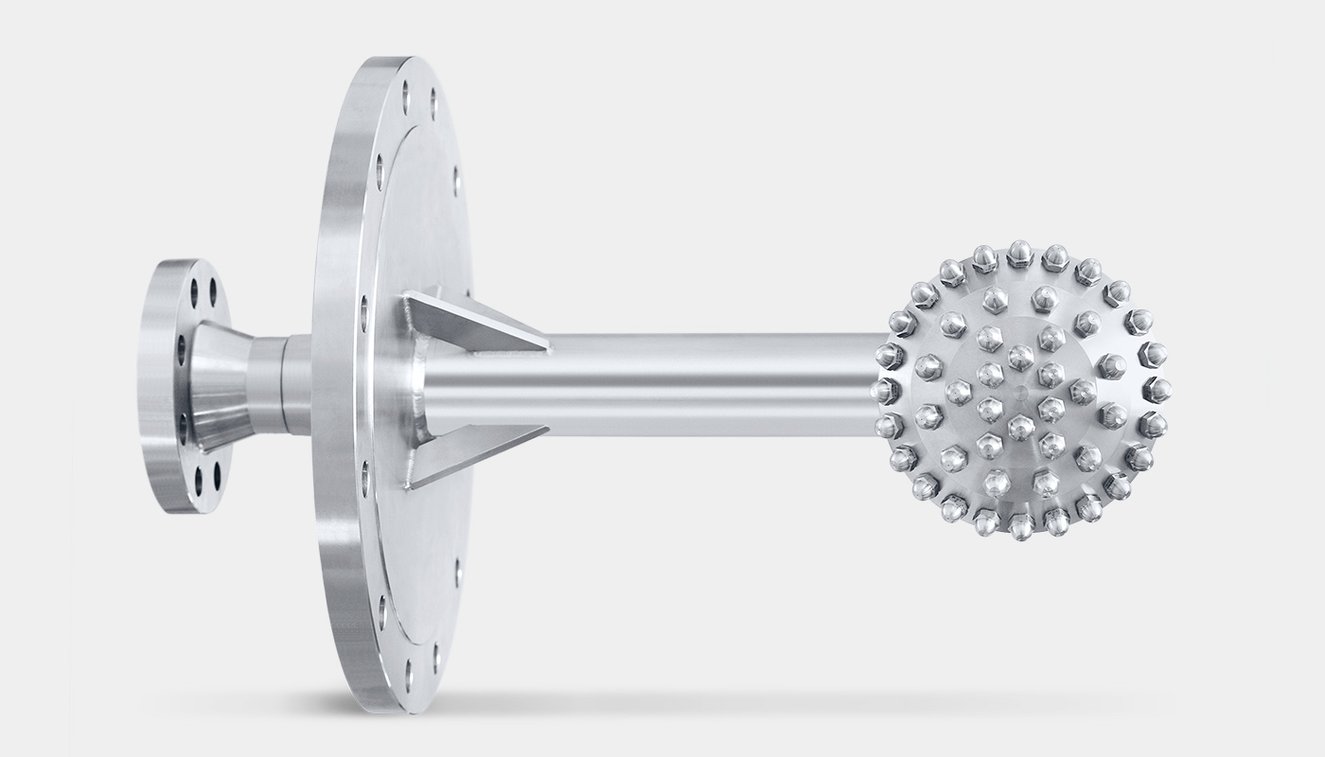

The nozzle heads can be combined with various types of nozzle (full cone, hollow cone) and are easily interchangeable. Through the diverse mounting options very different sprays can be achieved with variable liquid flow rates.

Materials: Acid-resistant stainless steel, heat-resistant stainless steel, brass, tantalum, titanium, hastelloy, inconel, PTFE, PP, PVC, PVDF, RCH 1000, other materials available on request.

SCHLICK nozzle heads are available in several models. With central or right-angled attachments (L series). Depending on the spray result desired the nozzle heads are fitted with SCHLICK full cone or hollow cone nozzles. If required these can be easily replaced by hand. So it is possible to achieve very diverse spray characteristics by using the same nozzle head. The liquid flow and spray angle of the nozzles (30–120°) are therefore completely adjustable.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

Nozzle heads are available in several models. Combined with various types of nozzle (full cone, hollow cone) very different sprays can be achieved with variable liquid flow rates. Nozzle head with full-cone nozzles.

Industrial Spray-unit pressure Model 60 (21 x Model 553) for maximum surface admission flow with smallest droplet sizes.

Variant for realising a large spreading cone with uniform volume flow density. Small droplet size by distributing the amount of liquid over many nozzles.

Model 60/8L with 48 of model 121 V for creating a large scatter cone with even flow rate density. Small droplet size through the distribution of the liquid to four nozzles.

Professional spraying is gaining much more in importance as a technique, especially in the production of MDF board, as it is a very helpful way of reducing costs while maximising quality at the same time. With its newly developed SCHLICK Blowline, Düsen-Schlick is setting new benchmarks for the widely used technique of blowline gluing.

Read moreDue to poor or incomplete combustion of the medium, soot is produced, and at the same time the emission values in the combustion chamber increase. With liquid fuels, combustion always takes place in the gas phase: The liquid fuel is first atomised, then vaporised, mixed with air, and finally burned in the gas phase. This article shows how atomisation can be influenced by various special nozzles.

Read more

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com