Spray pattern: circular hollow-cone

Spray angle: 40° – 100°

Orifices: 0.5 mm – 6.0 mm

Capacity: approx. 0.1 – 14 l/min at 3 bar

Spray pattern: circular hollow-cone

Spray angle: 15°, 30°, 45°, 60°, 75°, 90°

Orifices: 0.5 mm – 4.2 mm

Capacity: approx. 0.1 – 7 l/min at 3 bar

SCHLICK hard metal nozzles with a hollow cone spray image atomize static liquids into very fine droplets with a large specific surface and are very well suited to atomizing abrasive media at high and low pressures.

The quality of the atomized spray and the droplet spectrum are related to the diameter of the hole, the pressure, the scatter cone, the density, the viscosity, and the surface tension. In order to achieve fine atomisation high liquid pressures, low viscosities and surface tensions, small bore holes and a large spray cone should be aimed for. There is a low blockage risk due to a large, free cross-section. We guarantee operating safety up to 150 bar.

The liquid is fed under pressure and enters the swirl chamber through tangential slits or holes. In the swirl chamber, the energy in the pressurised liquid is converted into rotational energy or kinetic energy. A rotating film of liquid forms around an air core and emerges through the hole as a hollow cone jet. After overcoming the surface tension, the cone disperses into a myriad of fine droplets.

Materials: Acid-resistant and noncorrosive stainless steel, heat-resistant stainless steel, brass, hastelloy, other materials available on request. Orifice insert, swirl insert and chamber in carbide.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

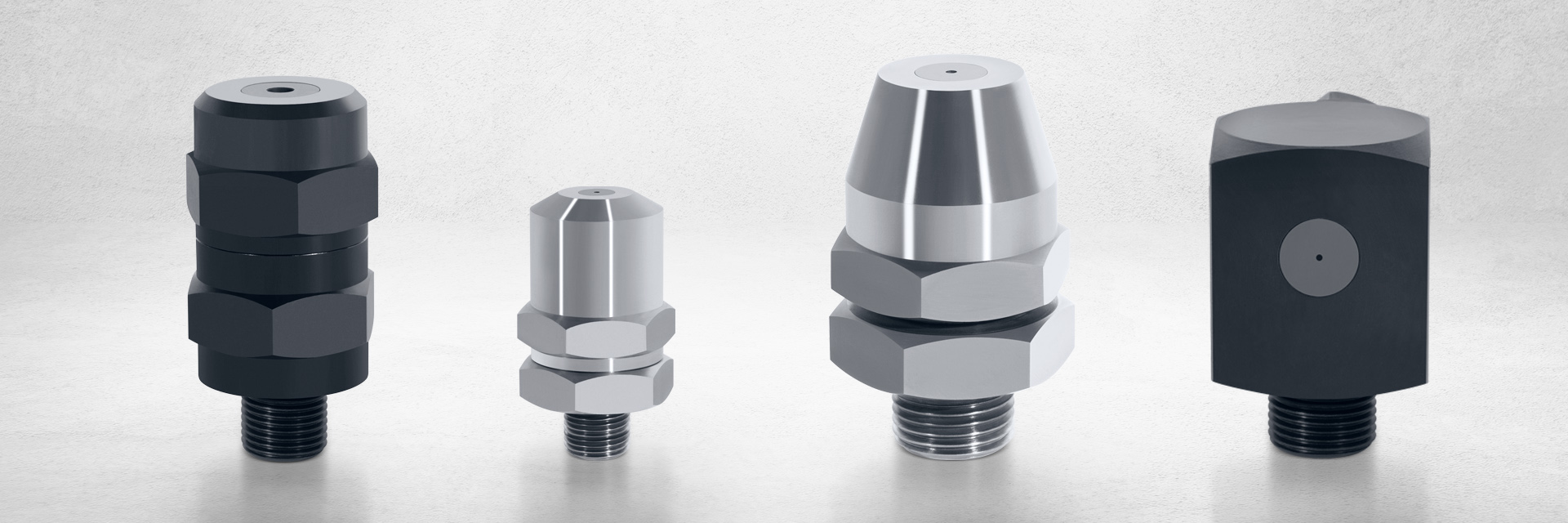

Model 118

for especially fine hollow cone atomisation. The nozzle exit and the swirl chamber are manufactured from hard metal (smoothed or unsmoothed). By easily exchanging the nozzle exit manually, many variations are possible, even in the spray cone. ø-bore hole: 0.5 – 6.0 mm (0.1 mm intervals).

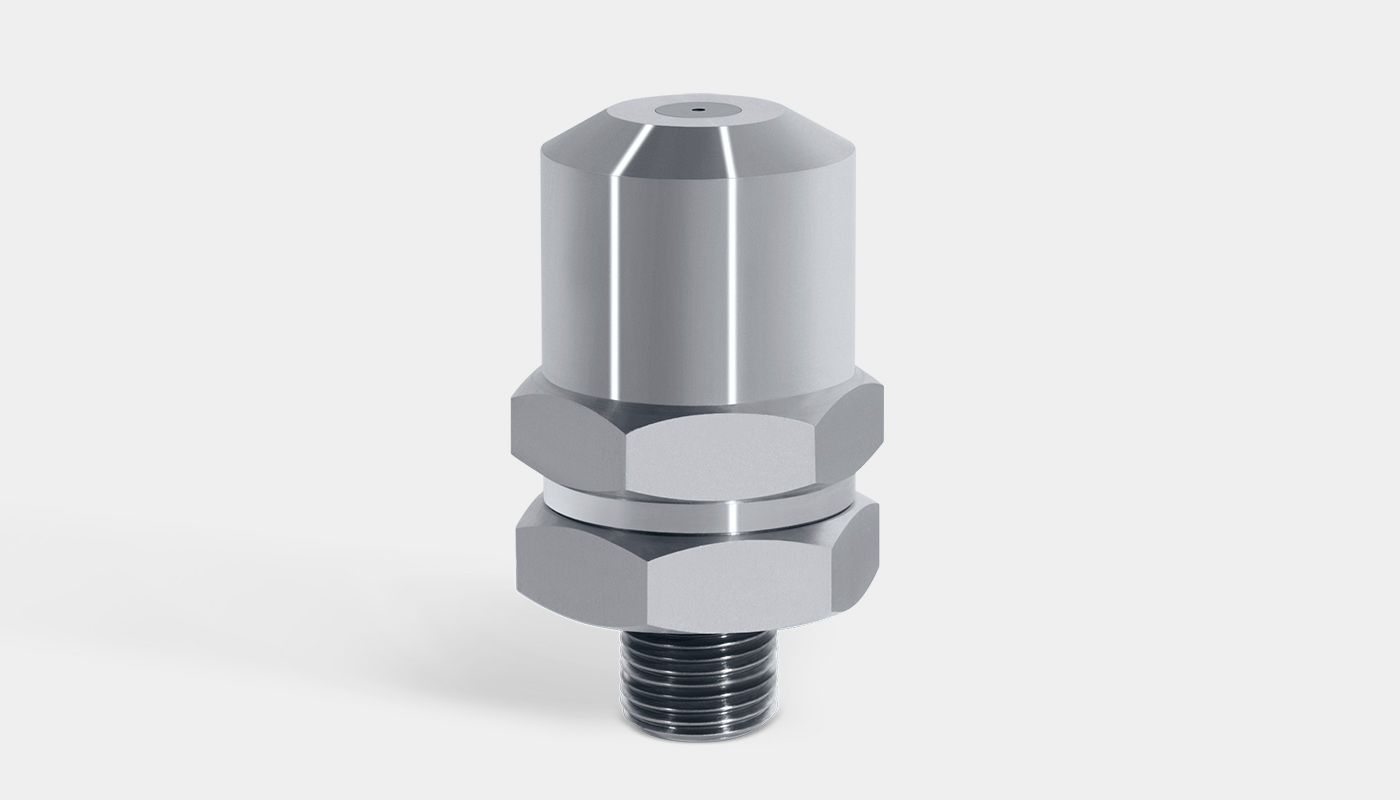

Model 202

The air flow performance of model 202 is comparable with the hollow cone jet model 100 and 200. The normal spray cone is 75°. The nozzle is however also available with 15°, 30°, 45°, 60° and 90° spray cones.

ø-bore hole size 1: 0.5 – 2.3 mm (0.1 mm intervals),

ø-bore hole size 2: 2.5 – 4.2 mm (0.1 mm intervals)

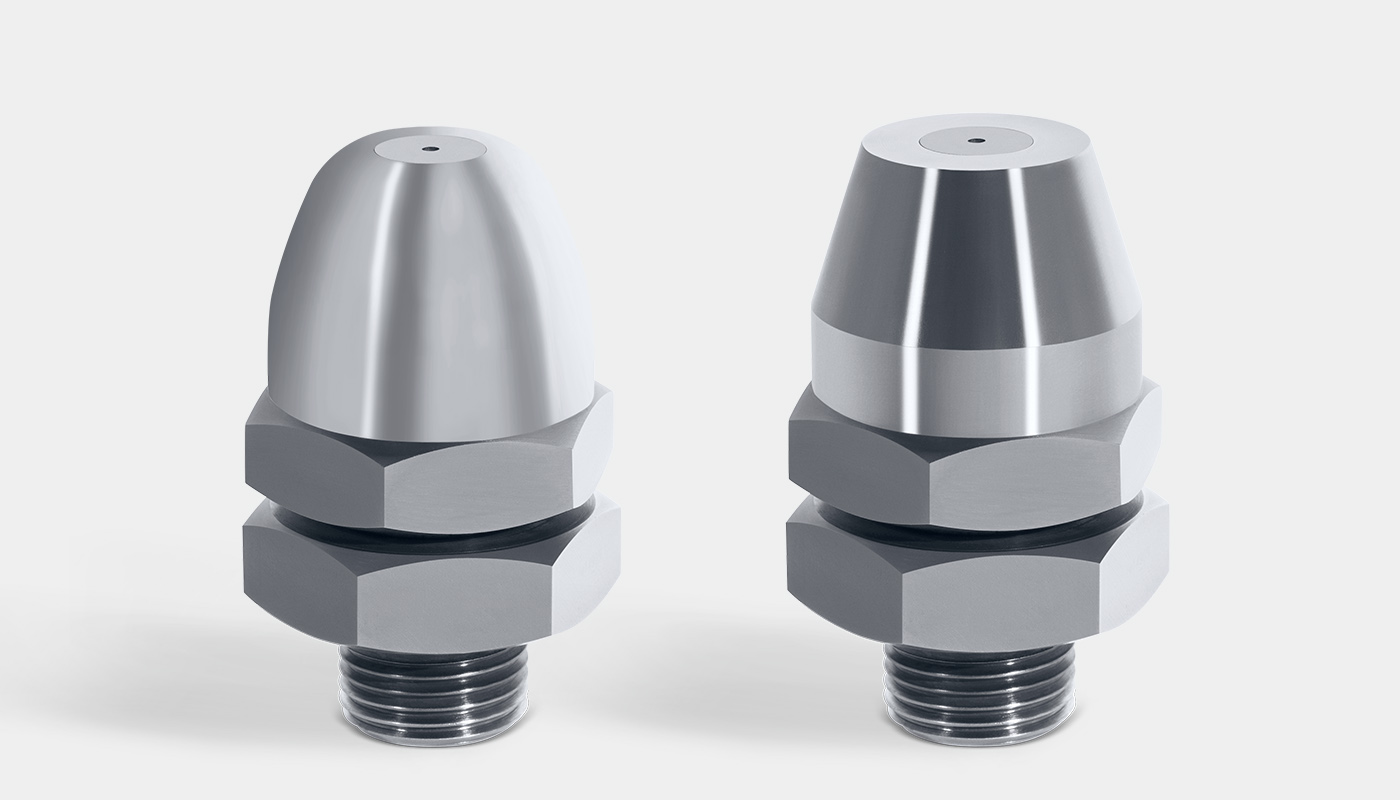

Model 432

Standard fittings for atomisation drying. The nozzle exit and the swirl chamber are manufactured from hard metal (smoothed or unsmoothed). Especially large air flow rates can be achieved through two tangential bore holes in the swirl chamber. ø-bore hole: 0.5 – 6.0 mm (0.1 mm intervals). Also available as a custom model with a rounded upper part to avoid build-ups.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com