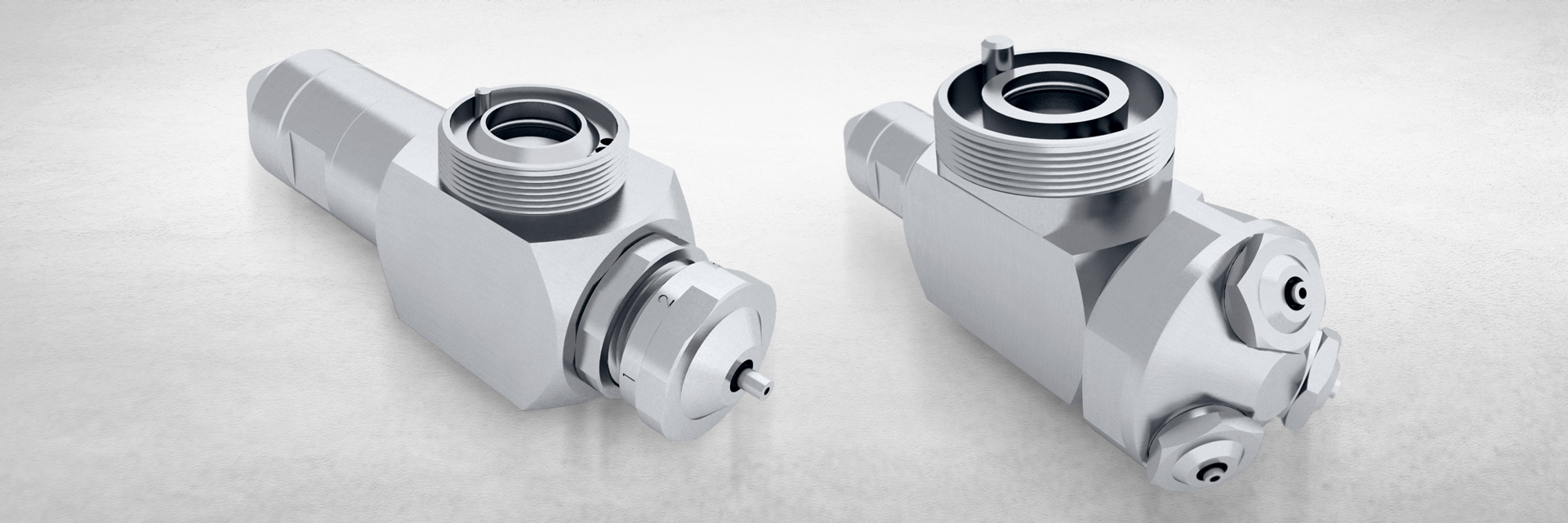

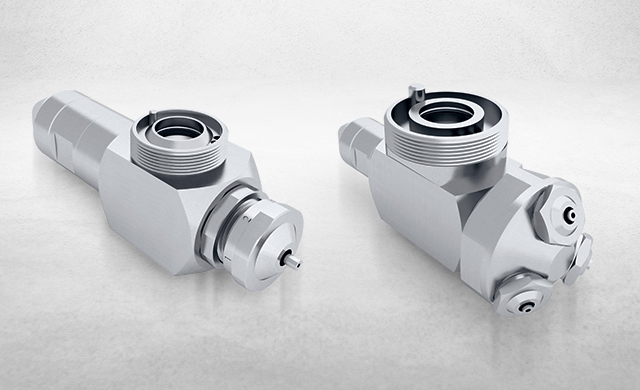

SCHLICK Pharma nozzles are characterised by a small, homogeneous and reproducible droplet size. Uniform liquid distribution across the entire spray width is guaranteed.

Depending on the application, different Pharma nozzles are used. These can be both pressure and two-substance nozzles.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

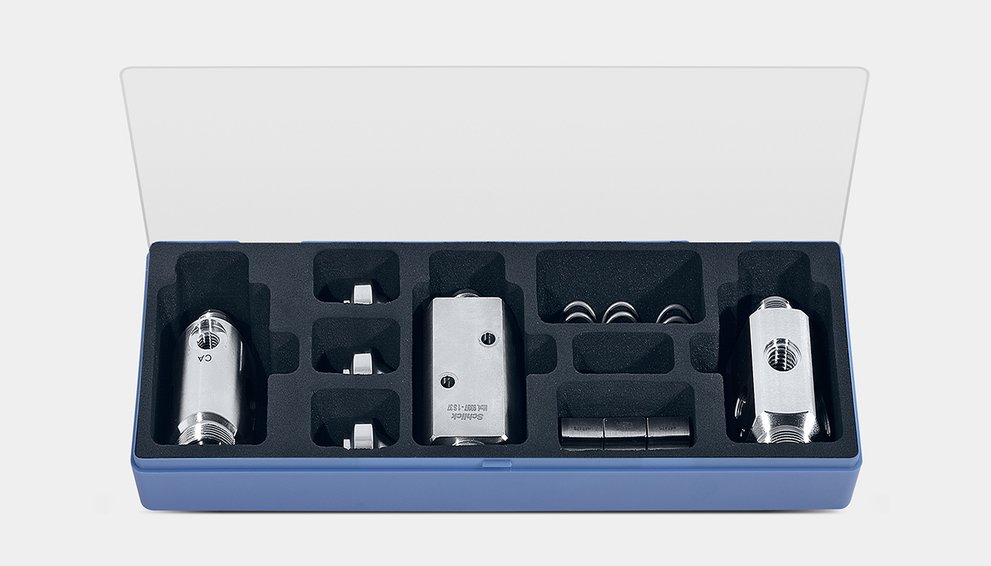

The SCHLICK ABC-storage box set for optimal protection against damage or loss of high class ABC-components of model series 930. Delivery without nozzle parts!

3 x nozzle body

3 x sealing cap

3 x spring

3 x fixing block

Portable control unit for two substance nozzles for easiest installations.

– 2 pressure adjusted air flows

– 1 control-air flow

– integrated pressure gauge

– adjustable peristalitc pump for liquid flow (Watson Marlow)

– Body: all Stainless Steel

Especially developed for a very wide range of applications in laboratory or smallest production systems. Also designed for operations outside of the system, for example for testing and optimizing processes.