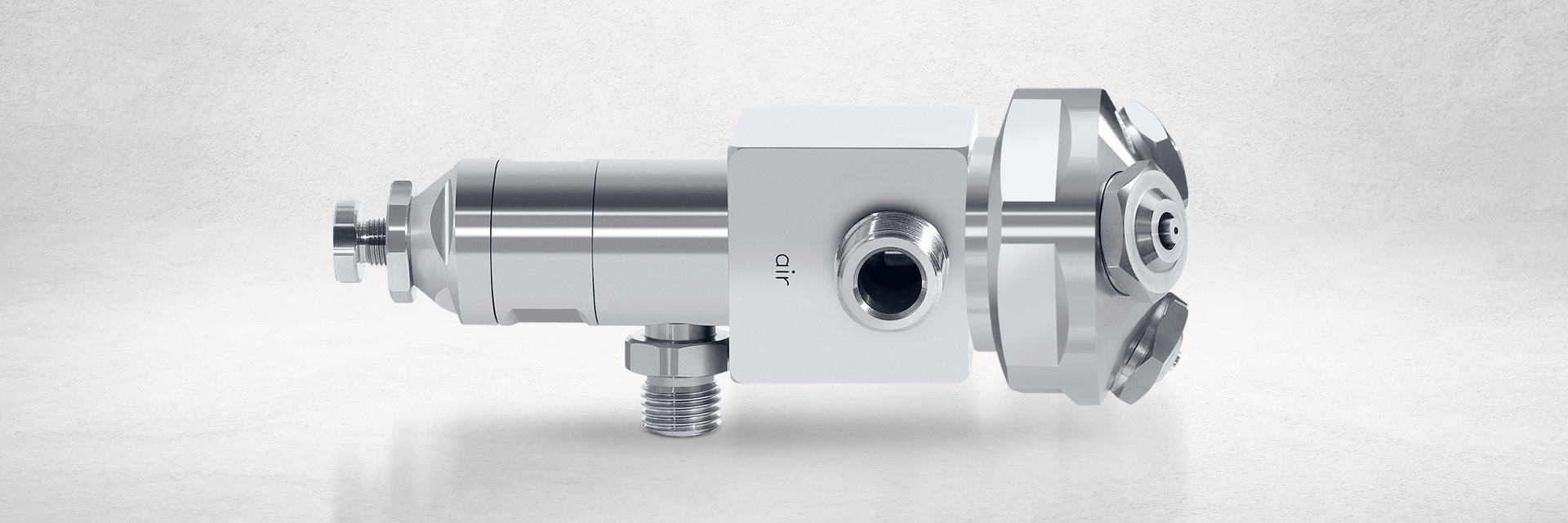

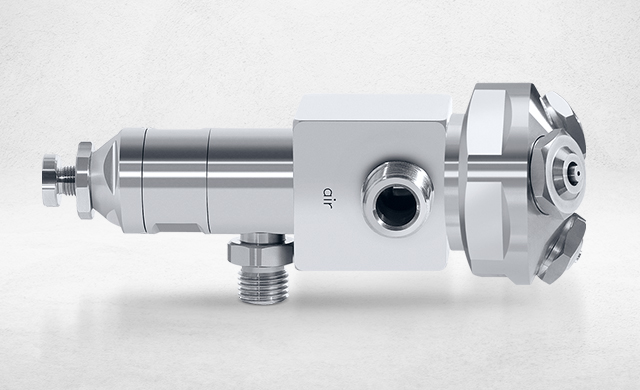

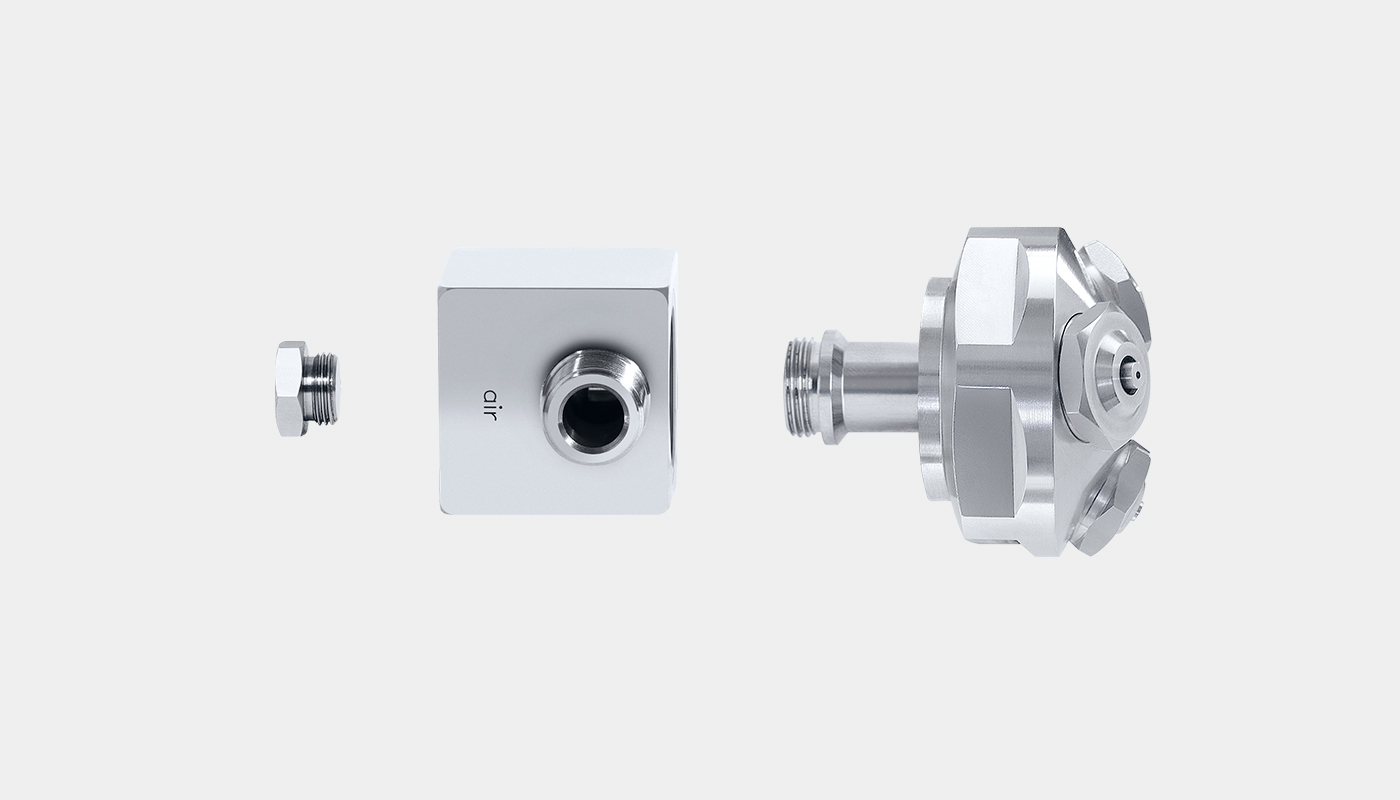

External-mix two-substance nozzles allow independent control of the flow rate and fineness of the atomisation. The flow rate for all models is controlled through the current liquid pressure difference. The SCHLICK model 937 is manufactured as a modular construction. This means that it can easily be rebuilt into other designs. Replacement parts are available for all individual parts, with reproducible results ensured.

Materials: Acid-resistant stainless steel, heat-resistant stainless steel, other materials available on request.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

Form 0

Basic model with dummy plug. Designed for the atomisation of liquids that are either siphoned or fed by gravity at a slight gradient. For homogeneous distribution on large specific surfaces.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

Blocked spray nozzles are a widespread problem in fluidised bed systems in which very fine or tacky products are processed. By using ABC nozzles, the pharmaceutical excipient manufacturer DMV Fonterra Excipients has succeeded in avoiding unplanned downtimes. Düsen-Schlick Anti-bearding cap technology (ABC nozzles) is well-established in the field of tablet coatings.

Read more

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com