SCHMIDT EHS rotating nozzles – flexible and efficient

When it comes to cleaning out blocked pipes or removing encrusted deposits from channels, rotating nozzles are incredibly versatile. Thanks to the flexibility in their design, they can be optimally adapted to requirements. SCHMIDT EHS rotating nozzles are produced in a variety of bore sizes – with nozzle exit units in the larger variants – and with a variety of angles, with front spray or back spray, for use in high-pressure hoses or lances. In nozzle variants with feed units, several backwards-facing jets provide the necessary pushing force and ensure the dissolved material is flushed out. A variant with a front spray is also available and is particularly suited for dealing with stubborn blockages in pipes.

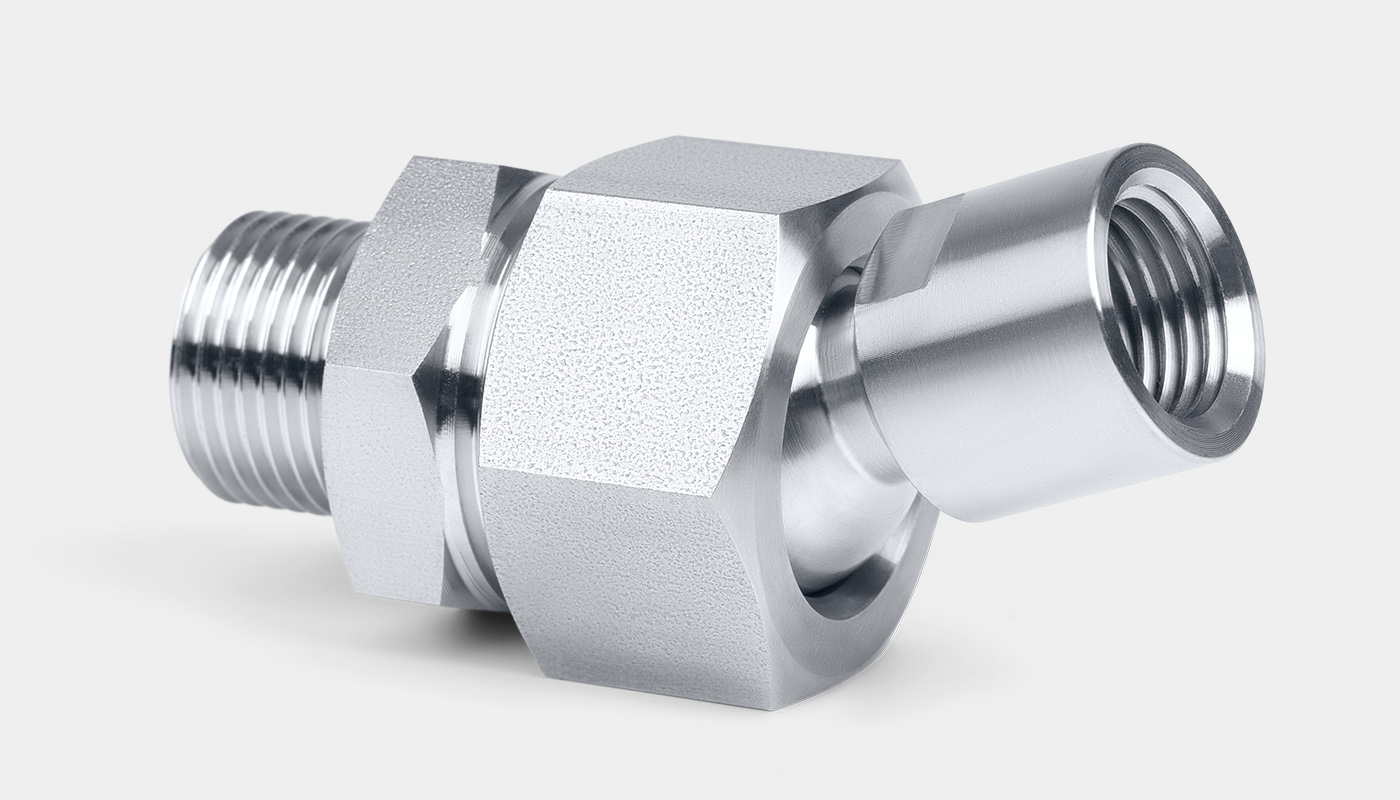

These rotating nozzles are compact and extremely stable by design. With working pressures of up to 1000 bar, even difficult cleaning work in pipes and channels can be quickly and easily performed.

The nozzles create a strong abrading effect due to the small impact surface of the core jet that rotates around the axis of the nozzle. This allows a large area to be abraded overall.

SCHMIDT EHS rotating nozzles have a long service life and require very little maintenance. A wide variety of designs offers solutions for a range of different cleaning applications. Depending on the model variant, a wide range of bores and spray angles are available. Custom measurements upon request.

Materials: High-grade steel/bronze. Other materials upon request.