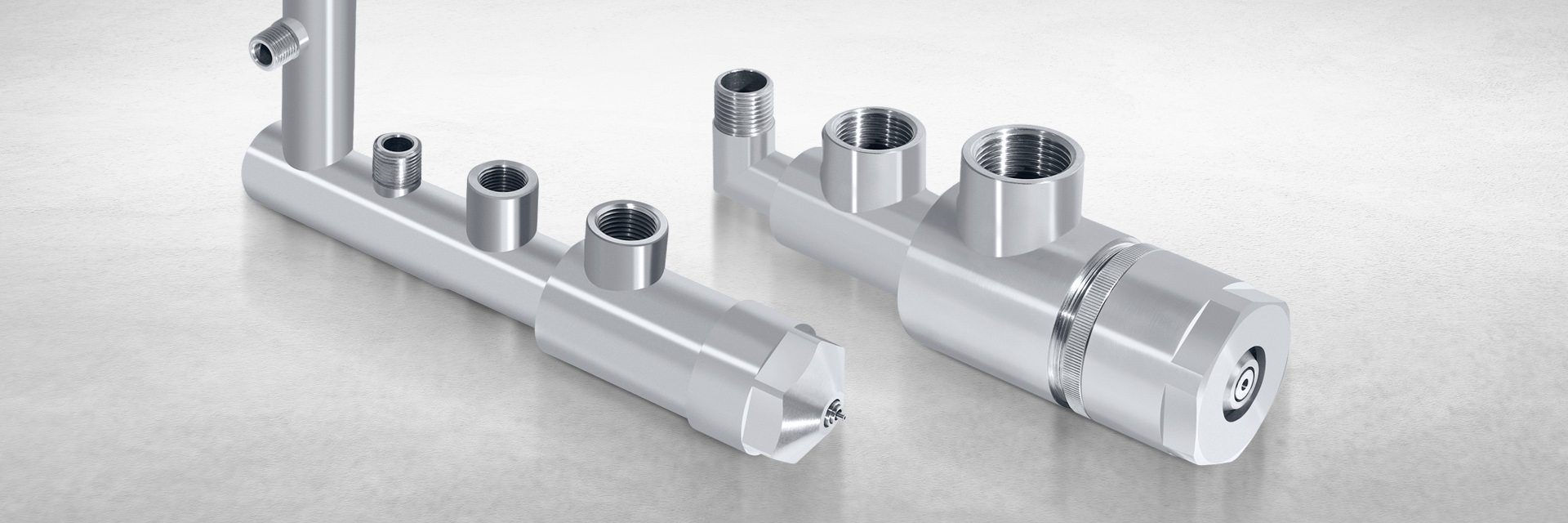

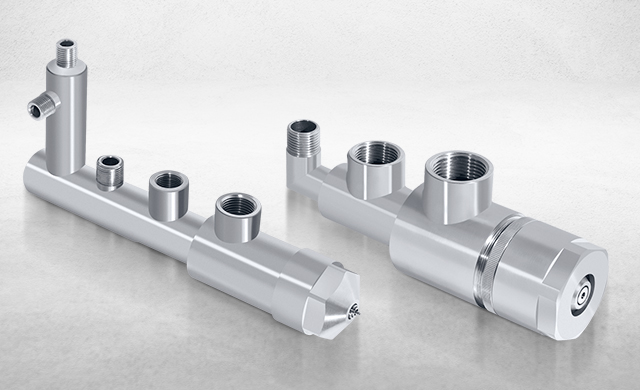

SCHLICK multi-substance nozzles allow very fine atomisation of several liquids with one nozzle and only one atomizing medium (air, gas or steam). At the same time, an extremely intensive mix of the liquids takes place when they leave the nozzle’s orifice. There is also the possibility of additionally feeding a channel with air, gas, or steam to ensure a larger area of exchange between atomising medium and liquid.

Reactions between the various liquids inside the nozzle are ruled out, as the media have no contact until they mix externally when leave the nozzle’s orifice.The droplet size can be individually set from the ratio of the drive media mass to the liquid mass. A liquid control range of 1:10 is achievable.

Materials: Acid-resistant stainless steel, heat-resistant stainless steel, tantalum, titanium, hastelloy, inconel, other materials available on request.

Two different options for controlling the SCHLICK three- substance nozzles:

1. Atomisation medium – Liquid – Atomisation medium

By selecting the appropriate cross-section even finer and more even atomisation is possible compared to the same air (gas or air) and energy consumption with a two-substance nozzle. The reason is the large interfacial surface between the atomisation medium and the liquid.

2. Liquid 1 – Liquid 2 – Atomisation medium

Two liquids are atomized simultaneously.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

For decades, Düsen-Schlick has been supplying systems manufacturers and cigarette producers with process-optimised atomisation technology. Moistening and flavouring are core processes in the primary stage of tobacco processing. These are ultimately responsible for the flavour and quality of the final product. Properly measuring flavouring additives and uniformly moistening leaves and ribs ensure optimum cutting and drying properties. This also creates benefits for the downstream (secondary) stage of cigarette production.

Read moreDue to poor or incomplete combustion of the medium, soot is produced, and at the same time the emission values in the combustion chamber increase. With liquid fuels, combustion always takes place in the gas phase: The liquid fuel is first atomised, then vaporised, mixed with air, and finally burned in the gas phase. This article shows how atomisation can be influenced by various special nozzles ...

Read more

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com