SCHLICK flat spray nozzles are suited to spraying both liquid and gas or steam media. Depending on nozzle model, spray angles between 20° and 160° are possible. Compared with liquid, the spray angle reduces by approximately 30° for gas and steam.

The degree of atomisation is related to the nozzle size, the capacity, and the differential pressure. Very fine droplets are achieved with small orifices and high pressures.

Materials: Acid-resistant stainless steel, heat-resistant stainless steel, brass, hastelloy, PVC, PVDF, other materials available on request.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

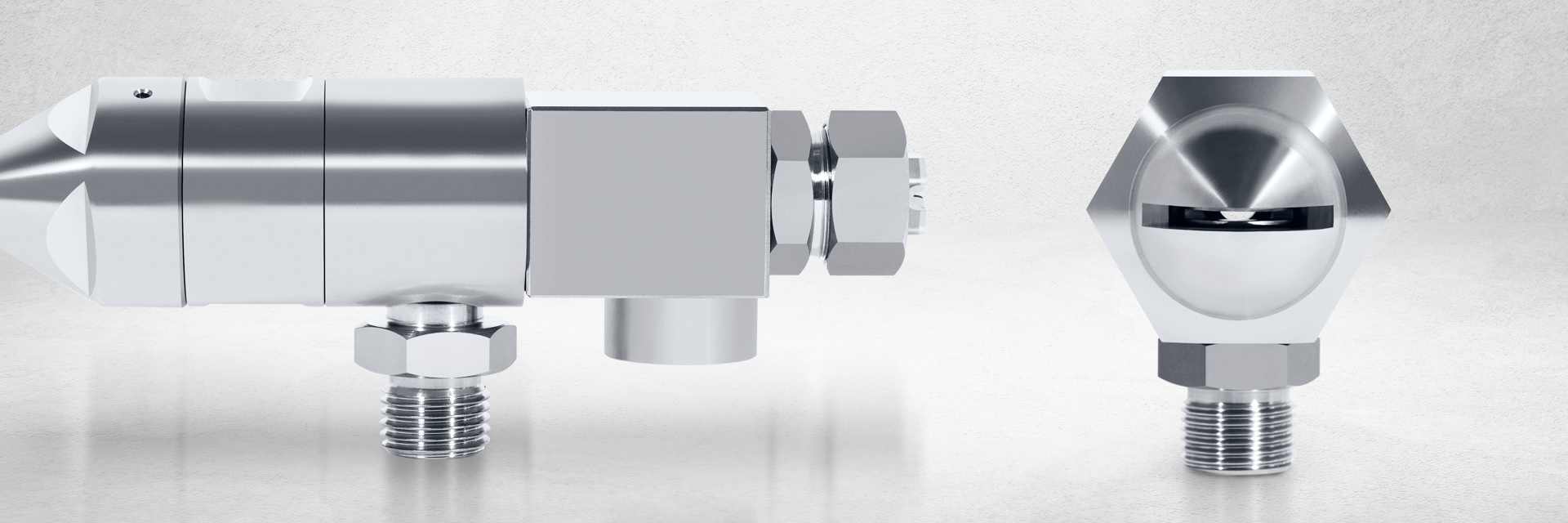

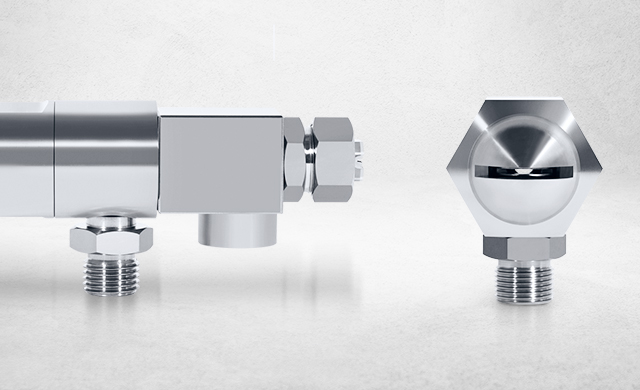

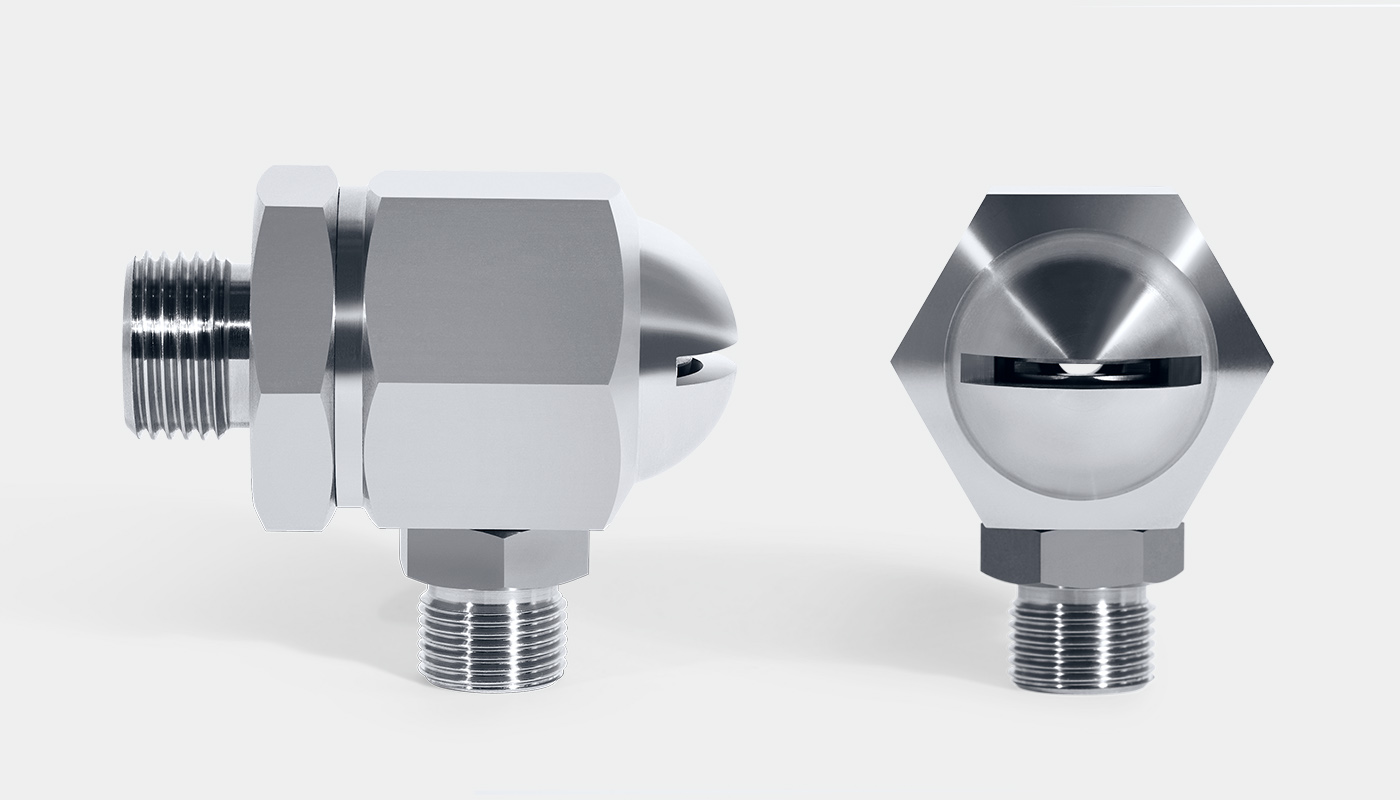

Model 650

Two-part nozzle construction with a nozzle exit, which is interchangeable and can be rotated.

Normal spray cone 90°, also available in: 30°, 45°, 60°, 120°

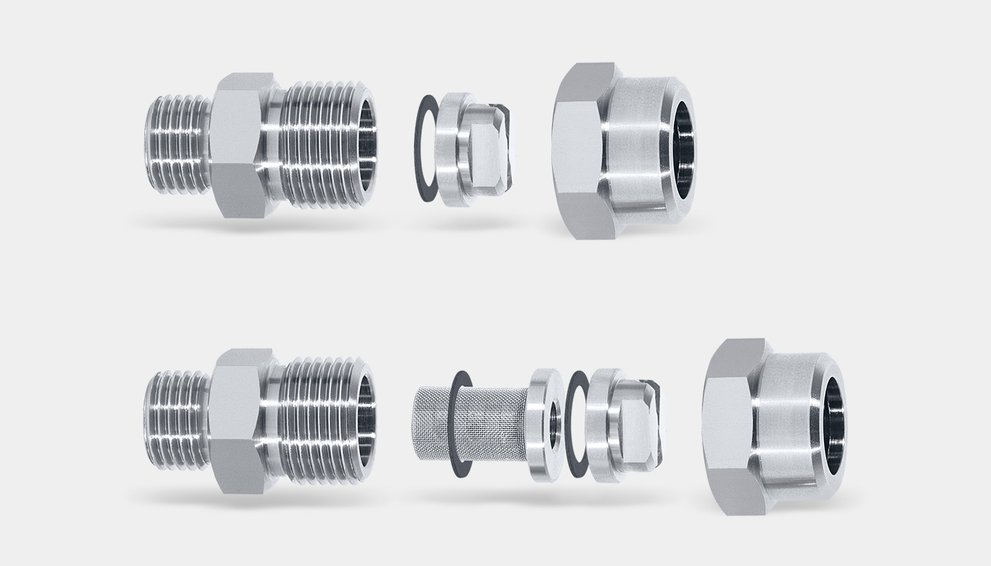

Model 650 (Size 0)

To avoid blockages in the exit, the smallest design of the SCHLICK fan nozzle model 650 (size 0) is also available with a filter. Due to the relatively large bore hole from size 1 these designs do not have a filter.

Model 650 Form 7-1

With pneumatic control through separate control air connection (atomising air does not have to be switched off). Nozzle needle closes automatically and abruptly. No dripping, even with pressurised liquids.

Model 650 Form 8

With solenoid valve / standard design: 230 V, 50 Hz, 100 % ED / ambient temperature: max. 55 °C / enclosure protection IP 65 / cycling frequency: limited only by the changeover time

Model 650

Reduced design for use in restrictive applications. No filter.

Normal spray cone 90°, also available in: 30°, 45°, 60°, 120°

Model 651

with pressed-in stabilisation unit for an especially homogenous spray image. Slotted, welded exit.

Normal spray cone 90°, also available in: 20°, 40°, 60°, 120°, 160°

Flat spray nozzles are suited to spraying both liquid and gas or steam media. Depending on nozzle model, spray angles between 20° and 160° are possible. Compared with liquid, the spray anglereduces by approximately 30° for gas and steam.

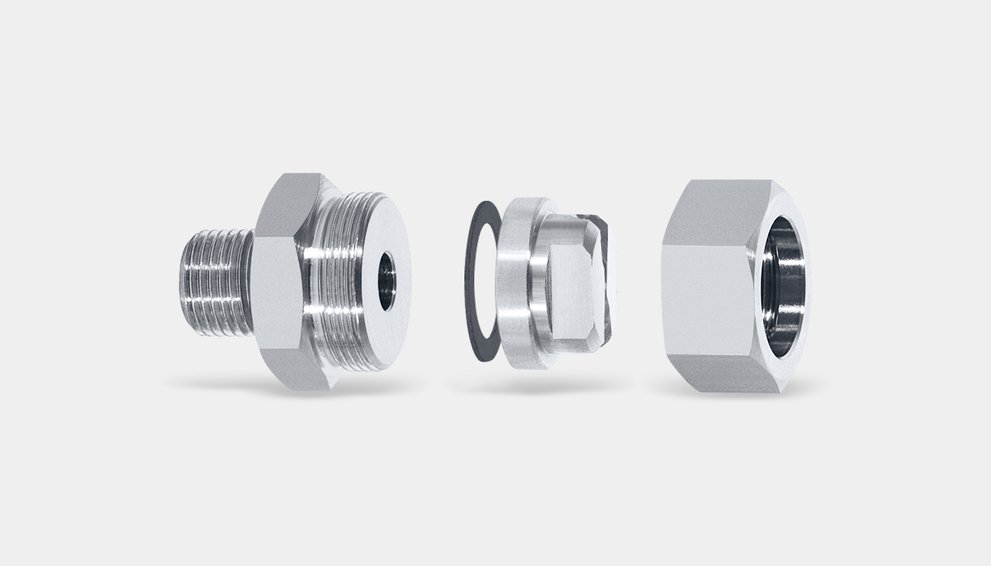

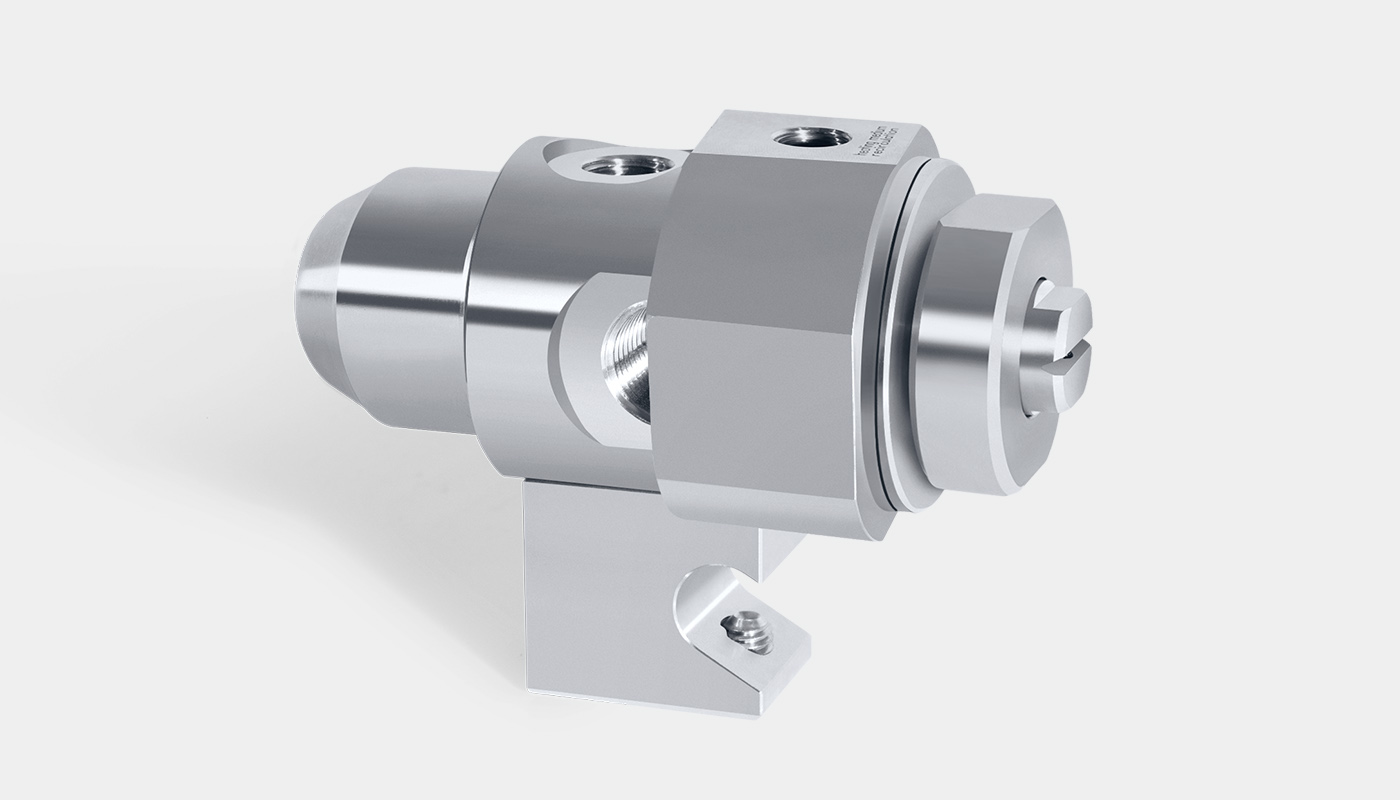

The coating nozzle 650/1 Form 7-1 S40 with heating jacket uses standard nozzle exit parts. Sealed upstream of the nozzle exit, it is therefore possible, amongst other things, to replace the nozzle exit when still under pressure. Optimised for pharmaceutical and food applications such as sugar coating etc.

The coating nozzle 650/1 Form 7-1 S40 uses standard nozzle exit parts. Sealed upstream of the nozzle exit, it is therefore possible, amongst other things, to replace the nozzle exit when still under pressure. Optimised for pharmaceutical and food applications such as sugar coating etc.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

Professional spraying in industrial wood machining, especially the production of boards, is gaining increasingly in importance. This is not just because of the increasing cost of energy and raw materials; it is also because increasingly high demands for quality in the manufacture of wooden boards encourage the demand for suitable processes and possibilities, in order to apply liquids as homogeneously as possible onto prepared base materials.

Read moreThe SNCR and SCR procedures were developed for flue gas denitrogenation in order to meet the strict air purification requirements. Injection lances for the defined insertion of the reducing agent are an important component of both processes. These differ in their structural and procedural design depending on the application.

Read moreDuring flue gas denitrogenation, the addition of a reducing agent is used to transform nitrogen oxides into a substance that can be emitted without causing any damage or can be used again. The reducing agent ammonia is increasingly being replaced by innocuous urea. However, urea has a tendency to crystallise during atomisation. When observing the nozzle systems used in urea atomisation, it can be seen that trouble-free operation is not always guaranteed.

Read moreCoating with sugar solution or chocolate is not only relevant in the food industry. In the pharmaceutical industry too, coating with sugar is used to mask taste and to preserve. Whilst traditionally the sugar solution is applied to the coated item by hand, the application in industrial processes is now carried out using nozzles, in particular those with a fan-shaped spraying pattern.

Read more

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com