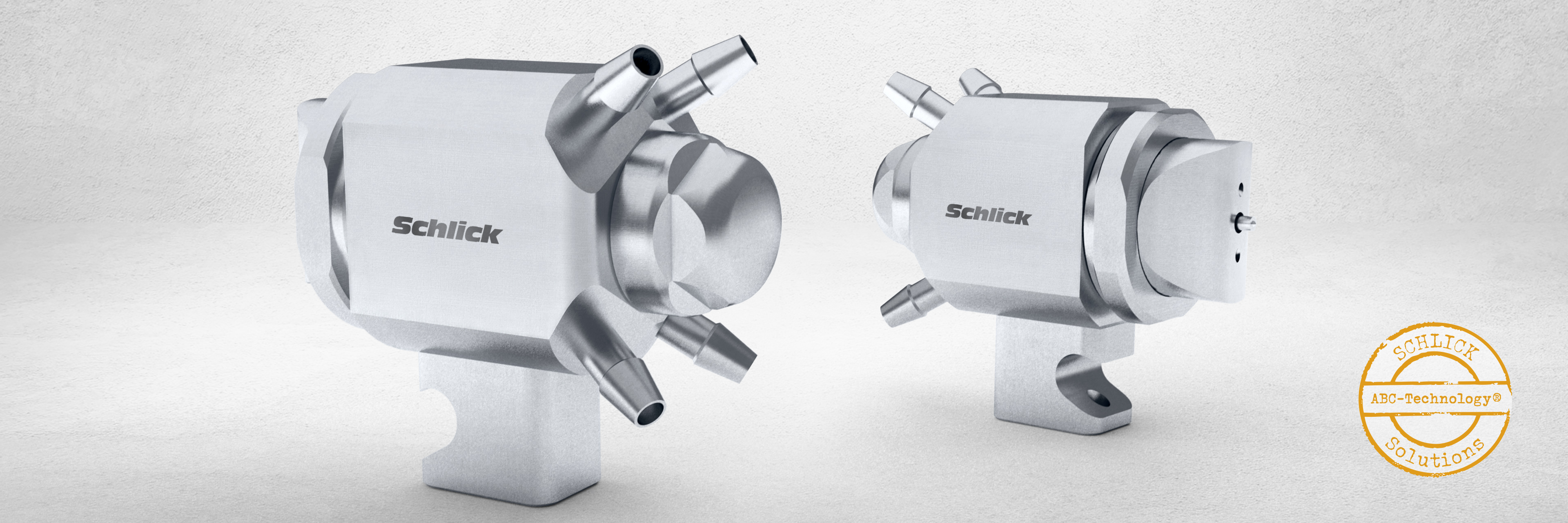

‘Simplify and optimise’ is SCHLICK’s motto when developing its solutions. For the S35 range with ABC-Technology®, the abbreviation EVO represents a powerful idea: the integrated connector. SCHLICK has fully integrated the hose connectors into the spray unit. It’s an idea that pays off for tablet coating in particular.

The new design has done more than just simplify handling and eliminate the additional costs of fittings: it has also significantly reduced the nozzle’s weight and the space it requires. At the same time, SCHLICK’s ABC air cap and spray quality remain completely unaltered. This has been investigated and confirmed using laser optics at the SCHLICK Test & Research Centre. There is also a White Paper guaranteeing identical results for the S35 range.

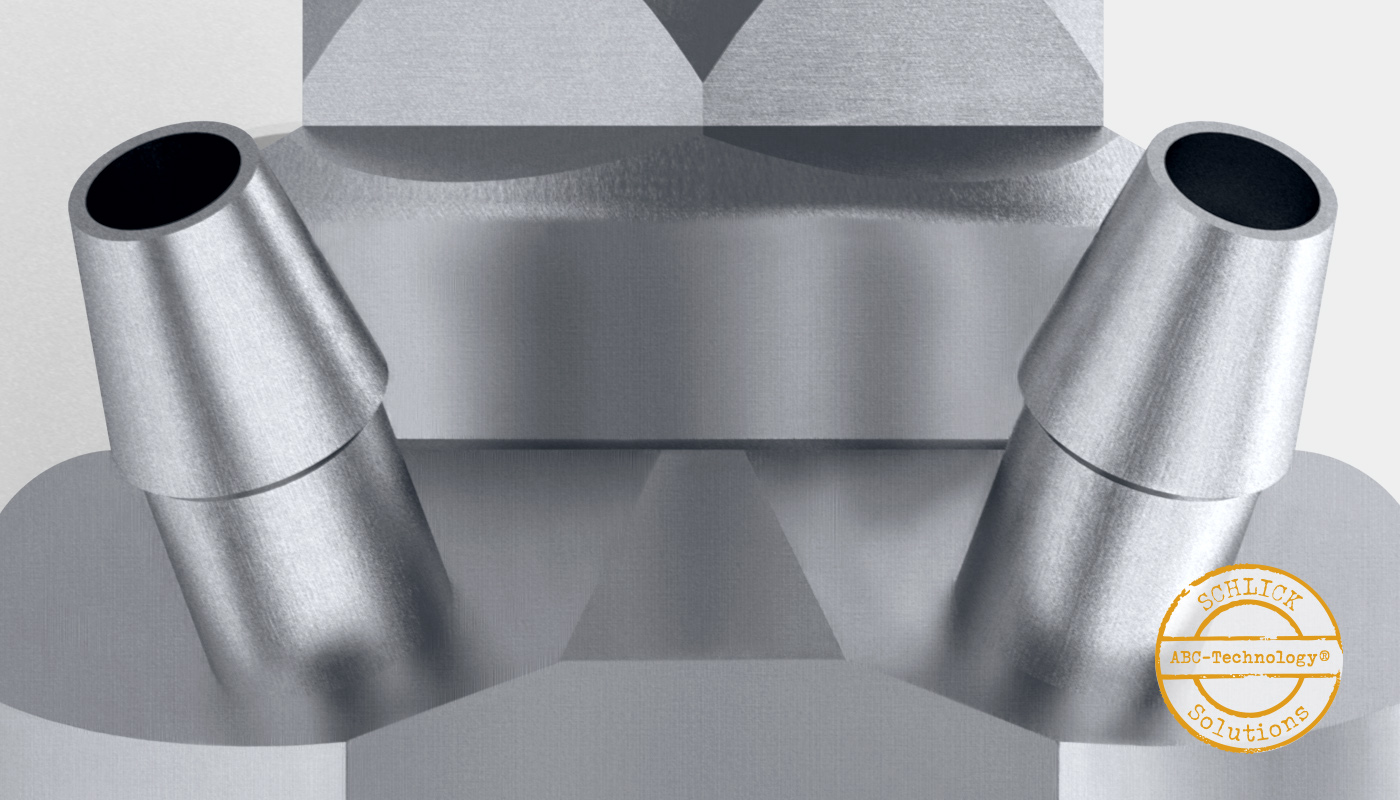

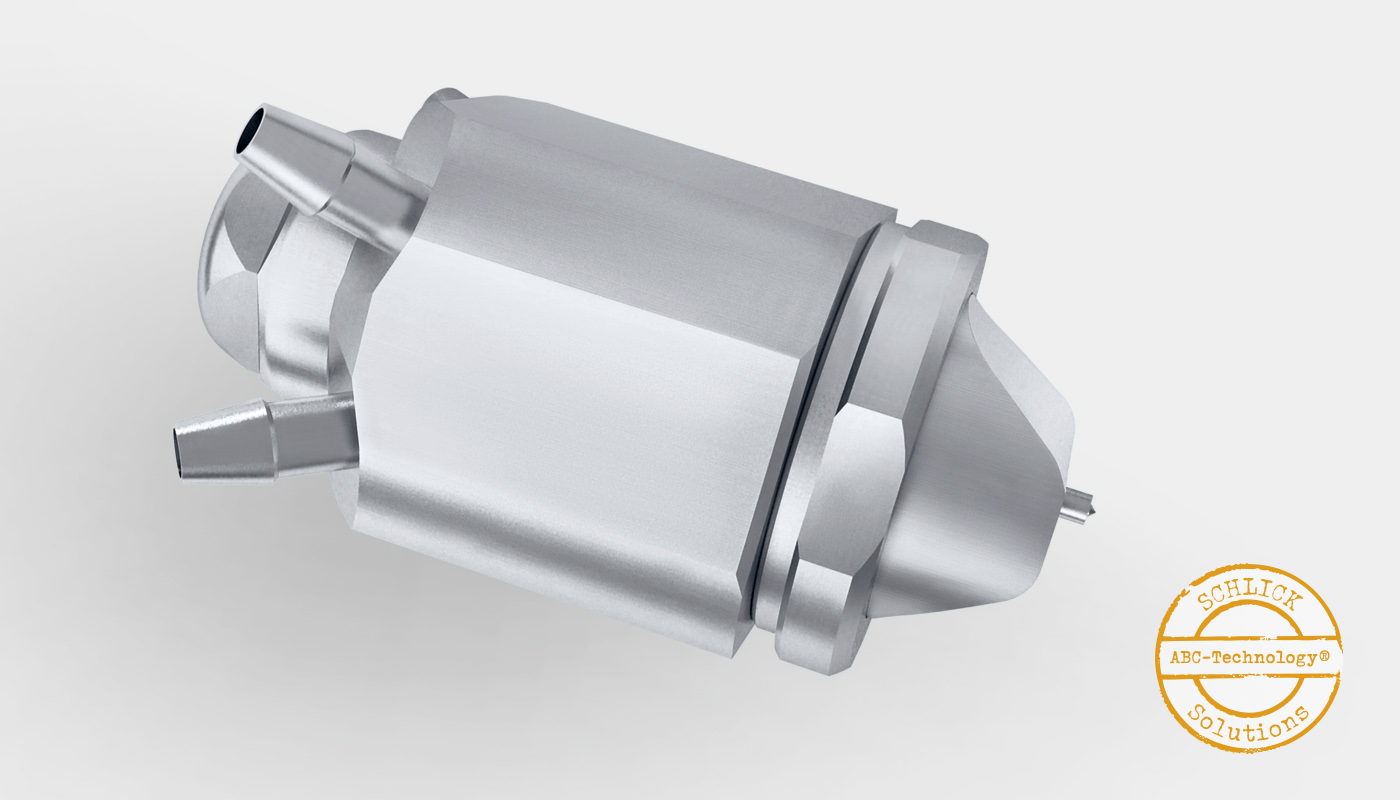

The nozzle unit with its built-in connectors is fabricated from a solid block of stainless steel. This has brought its weight and size down by 30%. The practical benefits of this are reduced turbulence, lower heating times and minimised condensation when used for coating applications. Meanwhile, the product is now easier to clean and maintain as there are no parts to remove.

Standard bore holes for liquid operation are available with 0.5 / 0.8 / 1.0 / 1.2 / 1.5 / 1.8 / 2.0 / 2.2 mm.

Alternative bore hole diameters are available on request. The nozzles are also available with and without liquid return system. ATEX version also available. Fixing unit for attachment to a rod (diameter = 10 mm) is inclusive; other diameters available on request.

Materials: FDA compliant 1.4404 (AISI 316L) materials, surface quality: Ra < 0.8. Other materials available on request.

Identical results – a white paper guarantees identical results from both S35 ranges.

Optimised processes – processing risks due to the use of incompatible adaptors are eliminated.

Easier to clean – cleaning is easier as no fittings need to be removed.

Less turbulence – turbulence in the coater is further reduced – and the thermodynamics of the process improved.

No additional certification – additional certification of materials and fitting seals is no longer required.

Easier handling – no additional tools are required for assembly/dismantling.

Improved flow profile – optimised flow profile with gentle transitions and no edges.

Less condensation – the risk of condensation forming is reduced to a minimum, especially with forced air circulation.

Shorter downtimes – the spray unit heating time is reduced.

The new 930 S35 ABC EVO. An optimised design for improved process safety with the same spray quality.

The massive 30% weight reduction could make the difference between being able to cover the entire tablet bed using spray technology and needing a separate nozzle to deal with the support rod.

The spray quality is identical to that delivered by our tried-and-trusted 930 S35 model. This has been investigated and confirmed using laser optics at the SCHLICK Test & Research Centre. There is also a White Paper guaranteeing identical results for the S35 range. The two models are within tolerances of ± 2% in terms of liquid flow, flow of the atomisation medium, spray angle, droplet size, droplet speed and droplet size distribution.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

Blocked spray nozzles are a widespread problem in fluidised bed systems in which very fine or tacky products are processed. By using ABC nozzles, the pharmaceutical excipient manufacturer DMV Fonterra Excipients has succeeded in avoiding unplanned downtimes. Düsen-Schlick Anti-bearding cap technology (ABC nozzles) is well-established in the field of tablet coatings.

Read moreImproved spray arm design and advanced nozzle systems cut set up time in half on state-of-the-art tablet coaters. This has big advantages for contract manufacturers who have find efficient ways of dealing with frequent changeover.

Read moreIn the pharmaceutical industry, flat spray two-substance nozzles are used in coating drums for the coating of pharmaceutical products. If possible, the coating process should not be interrupted for economical reasons. In addition to the geometry of the coater, the drying air and the spraying liquid, the nozzles play a particularly important role in this process. A new nozzle with an antibearding cap (ABC-Technology®) meets the requirement for operating security and improved handling during coating.

Read moreIn tablet production, coating processes require a lot of manual operation and experience: The spray arms and nozzles that are used have to be constantly checked, and the spraying process variables require careful adjustment. A new nozzle and spray arm concept now allows you to achieve considerably more efficient processes.

Read moreAnti-bearding air cap ensures that droplets are well distributed, and that coating and moistening are homogenous. The type of nozzle used for coating and moistening determines the process result. Normally, flat spray two-substance nozzles are used for this process. A new, robust air cap withstands even the most adverse operating conditions and thus ensures a clean spraying process with the ideal drop size.

Read moreTime and again conventional spray arms cause trouble when coating tablets. They are often difficult to clean and are not easy to inspect. The result is a disruption to the process flow and unnecessarily long set-up times. A new spray arm concept promises to improve this situation.

Read more

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com