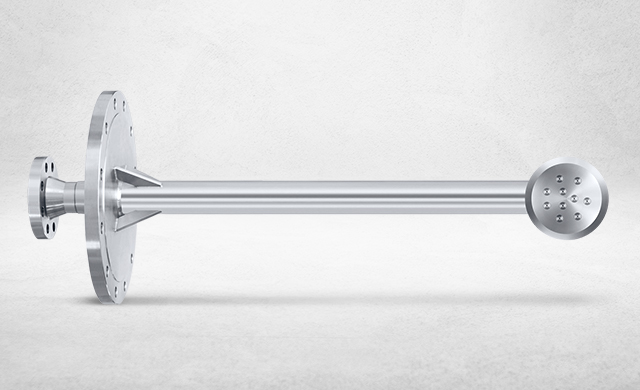

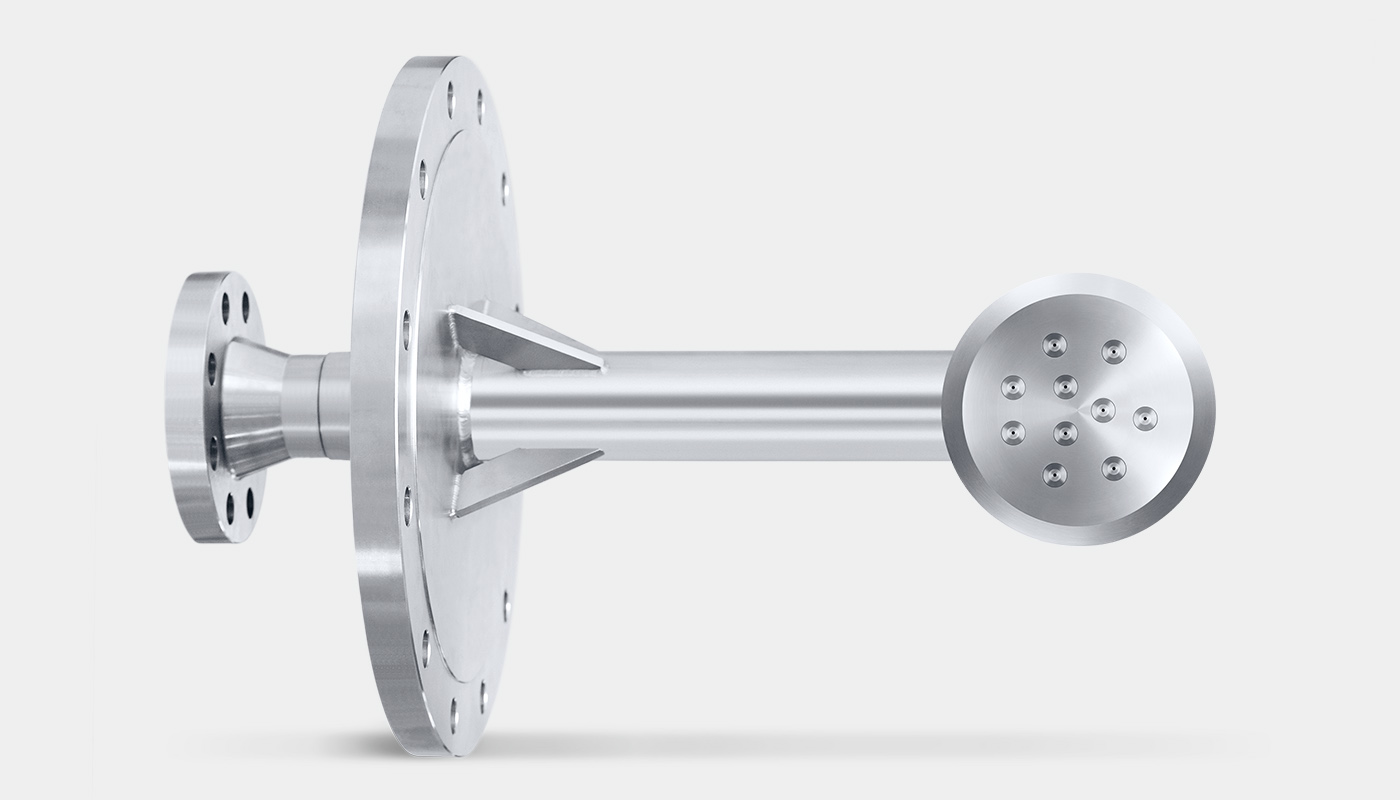

SCHLICK Industrial Spray-units pressure are available in very varied configurations and can be manufactured or adapted to customer specifications for the desired industrial application.

SCHLICK Industrial Spray-unit pressure, the version with a pressure nozzle or nozzles, can be fitted with any pressure nozzle (full-cone, hollow-cone, flat-spray, smooth-jet nozzles) or even entire nozzle heads depending on requirements and applications.

The flow rates and droplet sizes are dependent on the existing difference in liquid pressure. With pressure control, a liquid control range of 1: 3 can implemented. With smaller bore holes, however, pressure nozzles are susceptible to blockages.

Materials: Acid-resistant stainless steel, heat-resistant stainless steel, titanium, hastelloy, inconel, PTFE, PP, PVC, PVDF, other materials available on request.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

Customized design model 77 with 10 of model 120. Angled design with integrated and almost flat mounted pressure nozzles. Large scatter cone with even flow rate density.

Industrial Spray-unit pressure Mod. 60 (21 x Mod. 553) for maximum surface coverage with the finest possible droplets

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

For decades, Düsen-Schlick has been supplying systems manufacturers and cigarette producers with process-optimised atomisation technology. Moistening and flavouring are core processes in the primary stage of tobacco processing. These are ultimately responsible for the flavour and quality of the final product. Properly measuring flavouring additives and uniformly moistening leaves and ribs ensure optimum cutting and drying properties. This also creates benefits for the downstream (secondary) stage of cigarette production.

Read moreThe SNCR and SCR procedures were developed for flue gas denitrogenation in order to meet the strict air purification requirements. Injection lances for the defined insertion of the reducing agent are an important component of both processes. These differ in their structural and procedural design depending on the application.

Read moreDuring flue gas denitrogenation, the addition of a reducing agent is used to transform nitrogen oxides into a substance that can be emitted without causing any damage or can be used again. The reducing agent ammonia is increasingly being replaced by innocuous urea. However, urea has a tendency to crystallise during atomisation. When observing the nozzle systems used in urea atomisation, it can be seen that trouble-free operation is not always guaranteed.

Read moreDue to poor or incomplete combustion of the medium, soot is produced, and at the same time the emission values in the combustion chamber increase. With liquid fuels, combustion always takes place in the gas phase: The liquid fuel is first atomised, then vaporised, mixed with air, and finally burned in the gas phase. This article shows how atomisation can be influenced by various special nozzles.

Read moreDue to poor or incomplete combustion of the medium, soot is produced, and at the same time the emission values in the combustion chamber increase. With liquid fuels, combustion always takes place in the gas phase: The liquid fuel is first atomised, then vaporised, mixed with air, and finally burned in the gas phase. This article shows how atomisation can be influenced by various special nozzles ...

Read more

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com