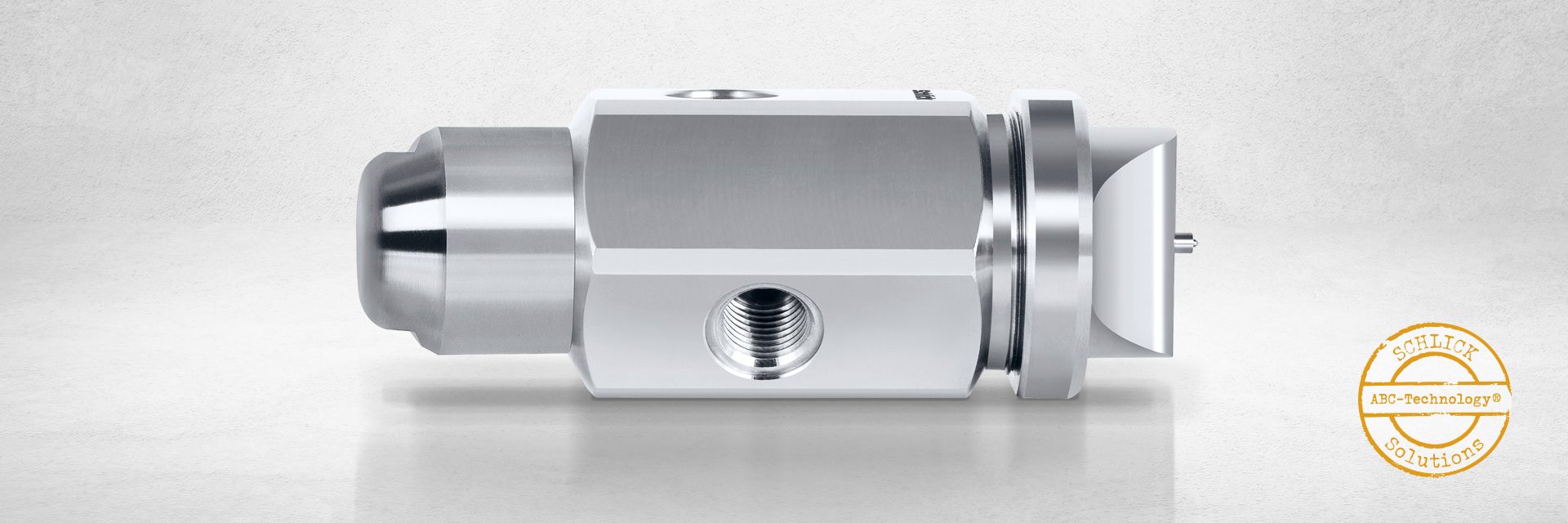

Thanks to the SCHLICK Anti-Bearding Cap (ABC) the sticking and build-up of deposits is prevented as far as possible. The GMP design also enables a very simple installation/de-installation for cleaning or servicing by hand. This leads to shorter downtimes and more efficiency in production.

The production nozzle model 930 Form 7-1 S35 ABC is designed with separate attachments for the pattern air (PA) and the atomising air (AA). So, there is more freedom for adjustment. Using the air pressure there are equally as simple and reproducible settings for the droplet size and the spray angle. For the first time upscaling from laboratory to production is possible due to the use of ABC-Technology® throughout.

Standard bore holes for liquid operation are available with 0.5 / 0.8 / 1.0 / 1.2 / 1.5 / 1.8 / 2.0 / 2.2 mm.

Alternative bore hole diameters are available on request. The nozzles are also available with and without liquid return system. ATEX version also available.

Materials: FDA compliant 1.4404 (AISI 316L) materials, surface quality: Ra < 0.8. Other materials available on request.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

Blocked spray nozzles are a widespread problem in fluidised bed systems in which very fine or tacky products are processed. By using ABC nozzles, the pharmaceutical excipient manufacturer DMV Fonterra Excipients has succeeded in avoiding unplanned downtimes. Düsen-Schlick Anti-bearding cap technology (ABC nozzles) is well-established in the field of tablet coatings.

Read moreImproved spray arm design and advanced nozzle systems cut set up time in half on state-of-the-art tablet coaters. This has big advantages for contract manufacturers who have find efficient ways of dealing with frequent changeover.

Read moreIn the pharmaceutical industry, flat spray two-substance nozzles are used in coating drums for the coating of pharmaceutical products. If possible, the coating process should not be interrupted for economical reasons. In addition to the geometry of the coater, the drying air and the spraying liquid, the nozzles play a particularly important role in this process. A new nozzle with an antibearding cap (ABC-Technology®) meets the requirement for operating security and improved handling during coating.

Read moreIn tablet production, coating processes require a lot of manual operation and experience: The spray arms and nozzles that are used have to be constantly checked, and the spraying process variables require careful adjustment. A new nozzle and spray arm concept now allows you to achieve considerably more efficient processes.

Read moreAnti-bearding air cap ensures that droplets are well distributed, and that coating and moistening are homogenous. The type of nozzle used for coating and moistening determines the process result. Normally, flat spray two-substance nozzles are used for this process. A new, robust air cap withstands even the most adverse operating conditions and thus ensures a clean spraying process with the ideal drop size.

Read moreTime and again conventional spray arms cause trouble when coating tablets. They are often difficult to clean and are not easy to inspect. The result is a disruption to the process flow and unnecessarily long set-up times. A new spray arm concept promises to improve this situation.

Read more

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com